Spring-Fast Military: NASM22529/1 Series

Cage Code: 0HES0

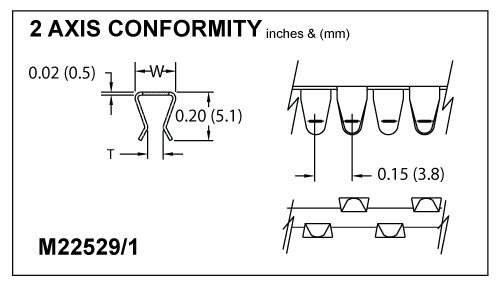

The MIL SPEC Series per NASM22529/1 has the lowest profile of any wire protection grommet edging available.

Its steel substrate is encapsulated with lubricious fusion bonded epoxy for superior abrasion and chemical resistance.

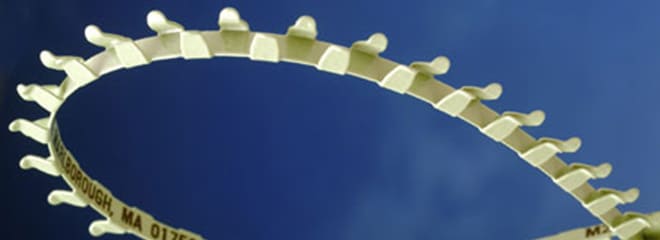

It has enhanced grip strength and is 2 axis conformable.

Key Benefits

- Superior performance: encapsulated stainless steel core: outperforms plastic grommets.

- Snap on installation lowers costs 49% vs. grommets with glue. Watch the 4 min. video below.

- Improves efficiency 9.5x – due to fewer steps in workflow.

- U.S. Defense Dept. FAA Acceptable: NASM22529/1 and National Stock Number: Federal Supply Code 5325.

Grommet Differentiation Table (GDT)

| Grommet Series | Castle Geometry | Flexibility | Polymer Coating | Extra Cushion | 100% TPE Encapsulation | High Heat | Mil Spec | Application Method | Notes |

|---|---|---|---|---|---|---|---|---|---|

| NASM22529/1 | Alternating | 2 axis | Yes | No | No | 285°F/140°C | Yes | Snap on/No adhesive | No cure time delay |

| FOR REFERENCE | |||||||||

| MS21266 Nylon | Opposing | 2 axis | NA | Yes | NA | 257°F/125°C | Yes | Adhesive Required | 8-24hr cure time delay |

| MS21266 Teflon | Opposing | 2 axis | NA | Yes | NA | 527°F/275°C | Yes | Adhesive Required | 8-24hr cure time delay |

Applications

- Military use and in service worldwide on helicopters, military transports, tactical equipment and C4 Electronics

- Aerospace use on business jets and general aviation aircraft and related avionics and electronic systems

- Straight edges, cutouts, access panels and knockouts

- Small radii inside or outside corners

Features

The old nylon grommet with glue is old, inefficient and costly. DTi has a better way.

- Epoxy encapsulated stainless steel substrate.

- Snaps on fast with finger pressure

- Installs continuously with two axis conformity

- Self locking with strong retention – no adhesives

- Simpler install: no adhesive, fixturing, curing, clean up or OSHA concerns, reduces installed costs

- Maintenance is far easier due to its ease of application and removal

- Customization available

Key Specifications

- Resistant to hydrocarbons, immersion, salt spray, shock and vibration

- Operating Temperature Heat continuous to -40°F to 285°F (-40°C to 140°C)

- UL94 V-0 Flammability Rating

- High Shock and Vibration Resistance to rms G 41.7

- 8 sizes to fit edge thicknesses: 0.025” to 0.26” (0.6 mm to 6.6 mm)

- Available in custom cut lengths & factory pre-cut reels of 25 ft. (7.6 m), 100 ft. (30.5 m) or 500 ft. (152 m)

- Tools available: Installation roller, full by-pass shears, castle removal, measuring scale,

- go / no-go sizing gauge, cutter cart

Qualifications

Spring-Fast® Product Configurations M22529/1 M22529/2

Axis Conformity 2 2

Vicat Softening Point per ASTM D01525 Rate B N/A Cushion: Thermoplastic Elastomer

Per ASTM D1525 Rate B, ISO306

230°F (110°C)

Operating Temperature Range 285°F (140°C) 185°F (85°C)

-40°F (-40°)

Dielectric Strength:

Volts 60 Hz per NASM22529, Section 3.2.11000 1500

Substrate Type 304 Stainless Steel

Taber Abrasion Resistance Substrate Finish: Epoxy

Per ASTM D 1044

1 kg load, C17 Wheel

8 mg loss 5000 cyclesTPE Cushion: Per D1044

1 kg load, C17 Wheel

25 mg loss 1000 cycles

Finish Coating: Thermosetting Epoxy, Color: Lime Green per FED-STD 595, Color Number 14533

Salt Spray Hours 500

ASTM B117, MIL-STD-202, Method 301

Immersion Per NASM22529 and Skydrol Compatible

Random Shock & Vibration MIL-STD-1344, Method 2005.1 Test Condition VI, Letter J

Duration 8 hours longitudinal and 8 hours perpendicular, rms G 41.7

Flammability UL94V-0 - File No. E113553 NZMT2

MIL-STD-202F, Method 111A

FAR 25.853

Telcordia GR63 Core

Fabrication Options Reels: 25' (7.6m) & 100' (30.5m)

10 pack: ten 12.75" (32.4cm) strips

Custom cut lengths (see table below)

Federal Supply Class 5325 National Stock Numbers

and

NATO Part NumbersClick here for DTi's Cross Reference Chart for National Stock Numbers & NATO Part Numbers

Custom Cut Lengths

| Nominal Hole Diameter | Cut Lengths | Number of Castles | ||

|---|---|---|---|---|

| Inches | mm | Inches | mm | |

| 2 | 50.8 | 6 | 152.4 | 40 |

| 2.25 | 57.15 | 6.9 | 175.26 | 46 |

| 2.5 | 63.5 | 7.65 | 194.31 | 51 |

| 2.75 | 69.85 | 8.4 | 213.36 | 56 |

| 3 | 76.2 | 9.15 | 232.41 | 61 |

| 3.25 | 82.55 | 10.05 | 255.27 | 67 |

| 3.5 | 88.9 | 10.8 | 274.32 | 72 |

| 3.75 | 95.25 | 11.55 | 293.37 | 77 |

| 4 | 101.6 | 12.3 | 312.42 | 82 |

| 4.25 | 107.95 | 13.2 | 335.28 | 88 |

| 4.5 | 114.3 | 13.95 | 354.33 | 93 |

| 4.75 | 120.65 | 14.7 | 373.38 | 98 |

| 5 | 127 | 15.45 | 392.43 | 103 |

| 5.25 | 133.35 | 16.35 | 415.29 | 109 |

| 5.5 | 139.7 | 17.1 | 434.34 | 114 |

| 5.75 | 146.05 | 17.85 | 453.39 | 119 |

| 6 | 152.4 | 18.6 | 472.44 | 124 |